Braunton Engineering - North Devon Porsche Specialist

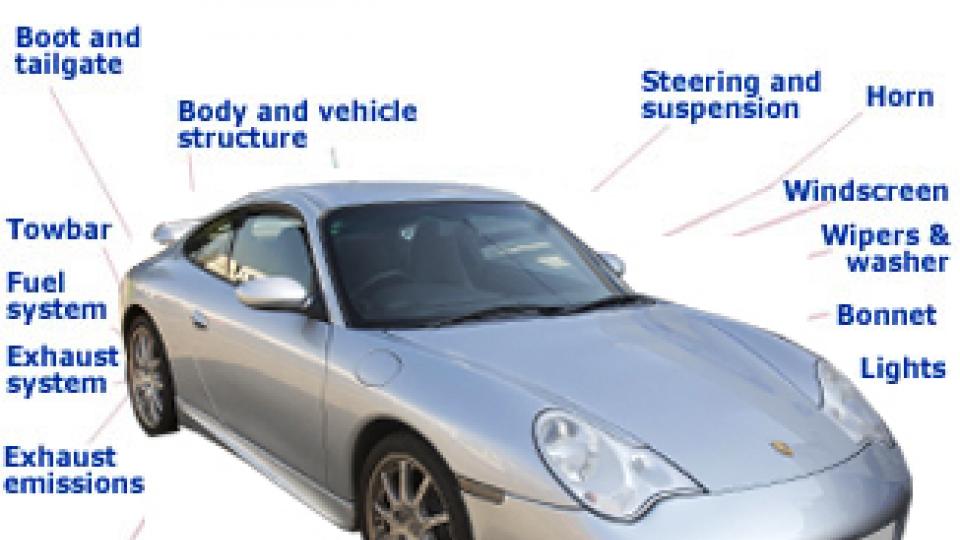

Welcome to Braunton Engineering, an independent Porsche Specialist dedicated to providing a great service experience. Located at a large high street garage & MOT test centre in North Devon, they offer dealer level facilities with state-of-the-art equipment.

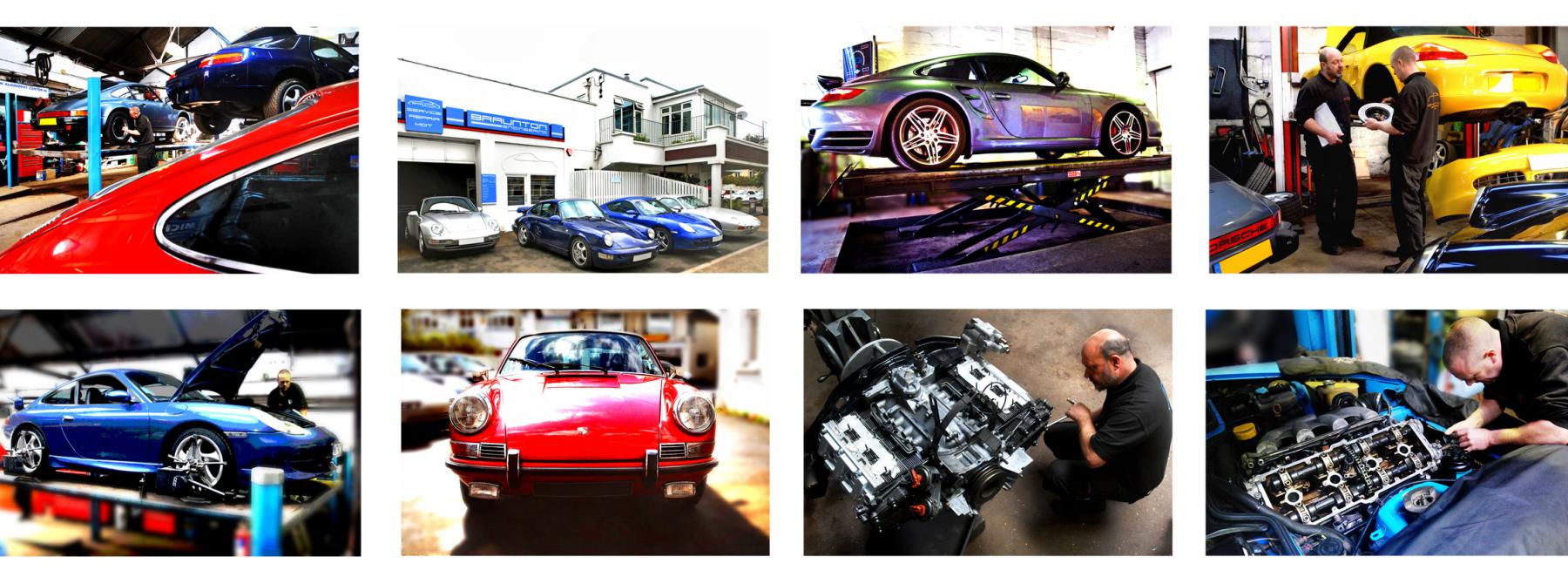

The staff form a knowledgeable team who have worked together for many years. They possess a wide and varied skill set with a great depth of brand knowledge from having repaired, serviced, rebuilt and traded Porsche's since the 1990's. Their ethos is that a well prepared car delivers both reliability and that unique Porsche driving experience.

The 300+ photos on the website represent a snapshot of the record of work undertaken in recent years. The photos form a record of a car's maintenance journey at Braunton, which some customers also like to include in their service history.

Their engineering prowess includes precision set-up & development of cars for track days and motorsport in the U.K. and the Continent.

The range of services for Porsche sports cars includes air conditioning, alloy wheel straightening, tyre fitting, body shop repair and performance upgrades. Staff expertise includes diagnostic & fault-finding, engine & gearbox building, suspension geometry setting and corner weighting.

Braunton MOT Station VTS No. 77290 has been established for over eighteen years and is proud of an exemplary record with the DVSA (Driver and Vehicle Standards Agency - Department of Transport).

Braunton Engineering provide Porsche specialist servicing, MOT Testing, maintenance service & repairs in the South West of England, Devon and Cornwall, Somerset and Wiltshire, and from across the U.K.

March 2020 - In addition to the routine maintenance work to:: 996 Carrera, 996 Cab, Boxster S, 928S misfire investigation, plus the regular MOT tests, the projects department is busy with: 997 front water pipes, 996 C4S IMS bearing replacement, 964 air-cooled engine build, 930 restoration final shake-down, a 964 engine repair to fix broken head stud and oil leaks, 928 Eibach motorsport suspension & track prep, V8 M3 race car final build with roll cage & preparation.

Regular maintenance of your sports car is crucial to ensure the car is performing at its peak and remains reliable and well preserved for future use. An annual service, or at least the minimum of an engine oil & filter change, is recommended for vehicles which are covering over 3000 miles per year.

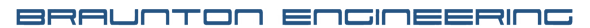

Using a set of procedures which are similar to the main dealer - the technician follows a check sheet of the factory service schedule which features jobs to complete and a list of specific visual inspections to grade the condition and function of the vehicle.

After visual scrutiny, the car is taken on a test drive by the assigned technician to assess the notes which were made when taking the booking. The vehicle is taken to the workshop and inspected on a ramp. If any work is required in addition to the menu price service, a cost-estimate for parts and labour is compiled for the customer's approval. If any queries are raised on the test drive, or during the inspection, the owner is then contacted to discuss these issues.

What do you get in a Porsche service? Braunton Engineering follows the Factory Service Schedule. This is an official service document for the mechanic to work through with the vehicle. The document features many parts, systems and functions of the vehicle which are both visually inspected, physically tested. The schedule will dictate which parts & fluids are due for change, according to the level of service which is due.

An example of the Major service: This includes the replacement of engine oil, oil filter/s, air filter, pollen filter, fuel filter, spark plugs (where applicable), using genuine filters and Mobil lubricants.

Attention to the tiniest Detail: Each 911 and Boxster, Cayman service at Braunton includes an analysis of the used engine oil and the oil filter! This is to check for metallic particles. Close scrutiny gives a good indication of the engine & IMS bearing's health.

This test is effective if the old oil & filter have been in the engine for at least a few thousand miles. Analysis of engine oil can give an early warning to an engine which is experiencing cylinder bore scoring, or an I.M.S. bearing fault.

Good history documentation is the key ingredient to finding a vehicle's market value. It is an essential track record of how the vehicle has been previously maintained.

If your service book which has been frequently stamped by Independent Specialists, and has a folder of receipts for the maintenance work completed in the past, it is a good indication that the vehicle has been driven and treated with respect by its previous owners. This is not written in stone, as there are exceptions to the rule, but the visual clues of the condition inside the cabin, of the bodywork, of the wheels, give an insight as to the previous treatment of the car.

Transparency: With a labour rate of £55 per hour +vat, they are committed to a transparency of cost-effective pricing and of good working practice. Any additional work is priced with parts & labour - an itemised cost-estimate for each job - keeping customers informed throughout the vehicle's stay.

Braunton Engineering welcomes owners into the workshop to inspect work whilst the car is in their care. Each vehicle is covered by comprehensive insurance whilst in the care of the team. The content of this website (images & text) and the marketing concept is copyright protected material of the author Chris Clopet.The business is VAT registered and correctly licensed with the authorities as an automotive repair garage - to recycle and dispose of hazardous waste responsibly.